BMW has developed a new version of its gear shift assistance system, “Motorrad Shift Assistant Pro,” which completely eliminates the need to use the clutch lever to change gears. Renamed “Automated Shift Assistant,” the system is expected to be available this year.

Slowly but surely, automatic transmissions are becoming prevalent in the motorcycle world. With the rise of scooters, even the most die-hard bikers have begun to appreciate the ability to change gears without using the clutch, while motards have started to value the true automatic transmission. This allows them to tackle alpine hairpin turns or long urban traffic stretches without arriving at their destination with a cramped left hand. It seems that more applications oriented in this direction will emerge in the future, initially offered on top-of-the-line models but eventually becoming more widespread as economies of scale make it feasible. Confirming this trend is the debut of BMW’s new “Automated Shift Assistant” system, the successor to the “Motorrad Shift Assistant Pro,” which already allowed shifting gears without engaging the clutch or throttle. The new device completely eliminates the clutch lever, serving as both an electromechanical assistant for manual shifting and an automatic gear-shifting system.

A specific button on the left handlebar lets the rider set the system to one of two modes, “M” and “D.” In “M” mode, the rider shifts gears at their discretion, but always under the system’s supervision to prevent commands that are not in line with the motorcycle’s functional state. In “D” mode, the system handles everything automatically, shifting gears based on the current riding mode. In both modes, the rider benefits from perfectly executed gear changes, with a smooth interruption of traction during both upshifts and downshifts.

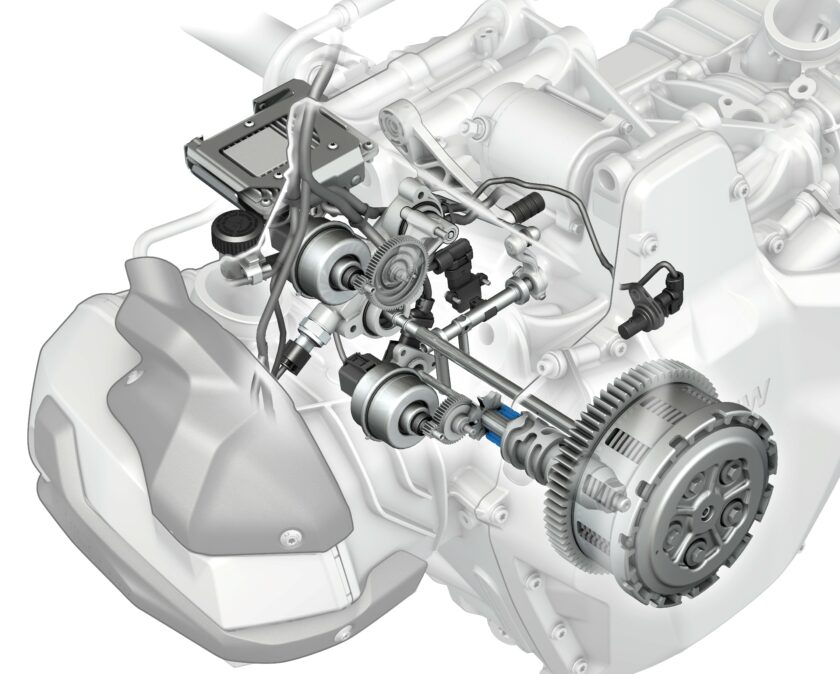

Constructively, the system is based on two electromechanical actuators that operate the clutch and gearbox, controlled by a specific control unit called the “Transmission Control Unit” (TCU). The TCU receives inputs from the engine control unit, a sensor on the gear lever, and other sensors that detect the transmission shaft’s revolutions and the clutch’s position. The clutch is operated by an electromechanical actuator capable of regulating clutch slippage, combined with a hydraulic system and a direct connection between the clutch’s master and slave cylinders. The system, as designed, will weigh slightly over two kilograms and is expected to cost around one thousand euros.